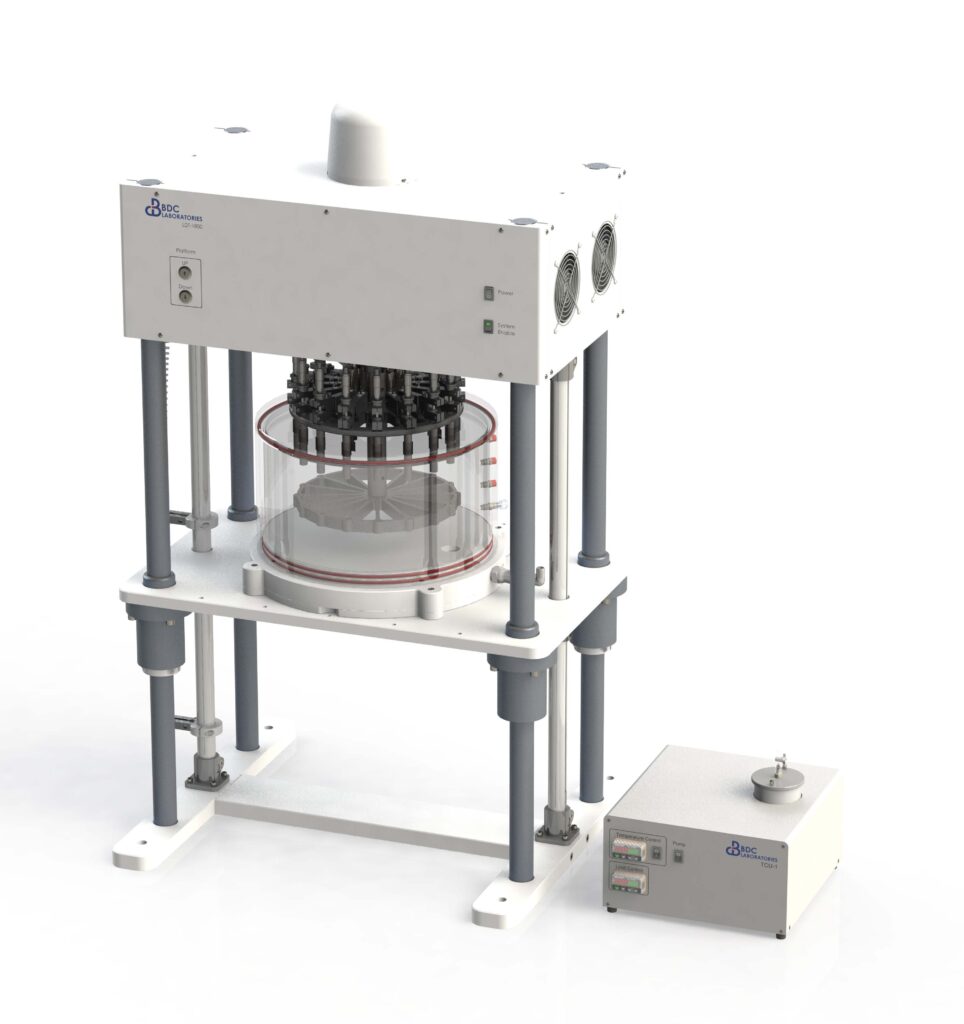

LDT-1800 Uniaxial Fatigue System

BDC Laboratories’ LDT-1800 Uniaxial Fatigue Test System is a structural heart / endovascular device focused system for mechanical fatigue, durability and dynamic characterization of materials, implant coupons, and full medical devices. The LDT-1800 test system employs an efficient and ultra-low friction electromagnetic drive technology to operate at a wide range of test frequencies and displacements up to 30 mm. The system is controlled with BDC Laboratories’ Statys® LDT control and monitoring software, providing a powerful and versatile platform for comprehensive fatigue and durability test management.

The optional Multi-Station Test Fixture is constructed with independent test station adjustability and optional dynamic load measurement, enabling the operator to easily preload and monitor each sample under test independently for response and fracture detection during S-N Endurance Limit testing. Through a standard mounting interface, the Multi-Station Fixture can be configured for numerous test sample geometries and technologies, including Stents, Stent Grafts, Heart Valves and Heart Valve Repair Devices. When combined with BDC Laboratories’ TCU-1 Heated Circulator Bath, all test samples can be fully immersed in solution and evaluated at a stable and consistent 37° C.

Move Forward with BDC

Specifications & Benefits

- Cost effective solution for precision fatigue and durability studies

- Base platform powered lift actuation to facilitate ease of sample mounting and access

- 50nm digital position encoder for highly accurate and repeatable cycling

- Peak Force: ±1512 N (±340 lbf)

- Stall Force: ±500 N (±112 lbf)

- Displacement: 30 mm

- Frequency: 0.1 to 100 Hz

- Power Requirements: 120/8 VAC/A Max (240/5 VAC/A Max)

Statys LDT Software

- Fully integrated software for precise test system control, with continual monitoring of all real-time measurements

- Tabular and graphic data presentation, including load hysteresis for a true appreciation of the test samples’ dynamic response

- Closed-loop control of driver to ensure repeatable and reproducible dynamic sample loading

- Real-time alarms and safeguards to protect both the system and test samples

- User-focused software environment to facilitate ease of system operation and monitoring

Accessories

- Multi-Station Fixture:

- The multi-station fixture assembly facilitates testing of up to 16 samples concurrently, with independent station adjustability to ensure correct and accurate conditions for each sample.

- Multi-Station Load Monitoring:

- With the multi-station fixture, individual load cells can be integrated into each station to facilitate continual load monitoring for identifying changes in sample dynamic response and real-time fracture detection.

- Heart Valve Commissure Fatigue Assembly:

- For prosthetic heart valve component commissure fatigue testing, BDC Laboratories offers a proven pulley-based deflection fixture designed to directly interface with the LDT-1800 fatigue system.

- Stent Dynamic Bending Fixture Assembly:

- To facilitate dynamic bending fatigue testing as detailed in ASTM F2942, BDC Laboratories offers an established column buckling-based fixture set for testing of stents of all diameters.

- Custom Test Fixtures:

- Based on years of testing all types of structural heart and endovascular medical devices, BDC’s R&D team is highly experienced at designing custom test fixtures to achieve a variety of loading and deformation boundary conditions.

- Heated Circulator Bath:

- BDC Laboratories’ TCU-1 is a heated circulator bath that connects directly to any sample immersion tank, creating a stable thermal fluid test environment. With remote temperature control measurement, the TCU-1 can control temperature to the actual sample bath rather than its own integrated reservoir.