Material Fatigue Strength Testing

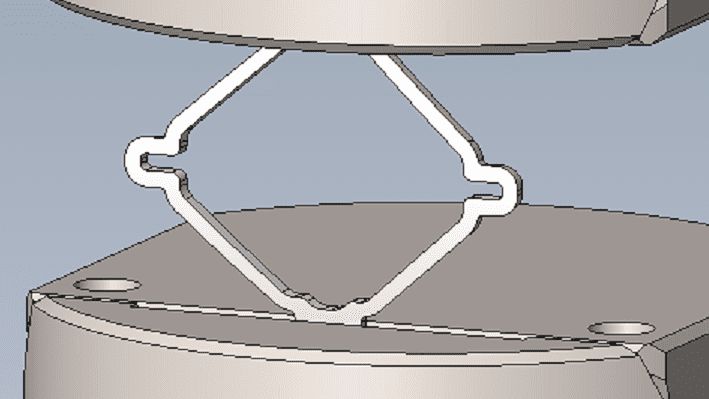

Medical device material fatigue evaluation using Finite Element Analysis (FEA) requires accurate stress-life (S-N) material characterization. The implant’s specific geometry and manufacturing processes can affect the S-N fatigue performance dramatically. Thus, regulatory bodies often require S-N material fatigue testing of coupon samples from the actual implant or a test sample representative of the implant. BDC Laboratories’ team is highly experienced in working with FEA experts to validate the computational model associated with coupon fatigue test samples, as well as planning the associated test load levels required for statistical based S-N fatigue characterization. The BDC team can further provide tolerance intervals associated with the S-N fatigue test data as part of a comprehensive study report that is suitable and ready for regulatory submissions.

Based on our extensive knowledge of material fatigue testing, BDC can offer a complete testing solutions as presented below. Our group is capable of supporting all aspects of the characterization, including developing the strategy, establishing protocols, validating methods, performing data analyses and providing regulatory quality final reports. Moreover, all test programs can be executed at a level consistent with the data’s application to optimize efficiency in time and cost, ranging from abbreviated early stage development studies to final, formal regulatory submission studies.

Move Forward with BDC

Testing Services

ASTM Standards

- F3211: Standard Guide for Fatigue-to-Fracture (FtF) Methodology for Cardiovascular Medical Devices

- E739: Standard Practice for Statistical Analysis of Linear or Linearized Stress-Life (S-N) and Strain-Life (ε-

N ) Fatigue Data

ISO Standards

- 5840-1 (Annex K), Cardiovascular implants — Cardiac valve prostheses — Part 1: General requirements

- 5910, Cardiovascular implants and extracorporeal systems — Cardiac valve repair devices