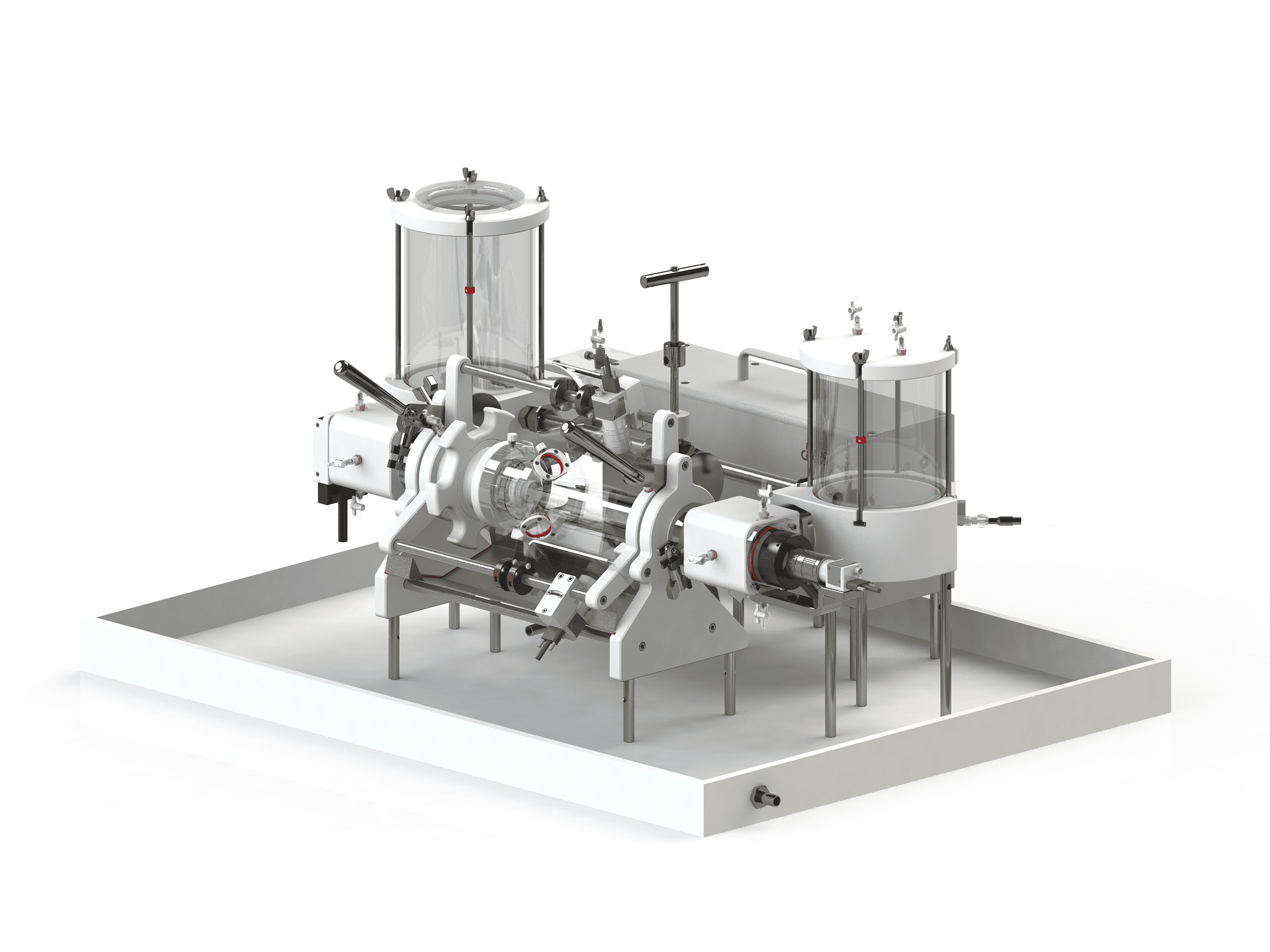

PQT-5000 Heart Valve Production Quality Test System

The PQT-5000 is the first pulsatile flow heart valve functional performance test system designed specifically for the production environment within a cleanroom. This highly advanced pulse duplicator system integrates key attributes such as rapid valve exchange for high throughput, multiple cameras to document leaflet kinematics and 21 CFR Part 11 compliant software that integrates both hydrodynamic waveform data and high-speed video. The heart valve is assessed against a battery of user-defined QA performance metrics, providing a clear pass-fail result for each valve in a rapid, reliable and highly consistent manner.

The PQT-5000 assesses the functional heart valve performance and leaflet kinematics through a range of parameters such as:

- Forward flow pressure drop

- Regurgitant volume

- Effective orifice area (EOA)

- Geometric orifice area (GOA)

- Coaptation center

- Central jet area

- Leaflet pinwheel

- Leaflet opening/closing dynamics

- Leaflet edge alignment

The PQT-5000 production pulse duplicator is an integrated test apparatus that includes atrial and ventricular chambers, a compliance chamber, peripheral resistance and a valve rapid-exchange mechanism and is driven by BDC Labs PD-1100 Pulsatile Pump. The test system interface is achieved through BDC’s Statys® PQT software. Following a detailed consultation with each client, BDC can customize our heart valve production test system for any specific heart valve production test requirements.

Move Forward with BDC

Specifications & Benefits

- Highly versatile for evaluation of all heart valve technologies

- Test article Rapid Exchange Mechanism

- Facilitates high throughput for heart valve evaluation

- Test fluid is maintained within the test system and at temperature during valve exchange

- Test system fully compatible with chemical sterilization

- Integrated high-speed video with image analysis to document performance (optional)

- Frequency: 30 – 190 bpm

- Stroke Volume: 0 – 300 ml

- Flow rate: 1 – 10 L/min

- Excitation Waveforms: Sine & Modified Sine

- Sample Sizes: Up to 80 mm

- Test Fluid: Saline, Custom

- Operating Temperature: Room to 50 °C

- Regulatory Compliance: 21 CFR Part 11 Compliant, and all applicable European Union directives and standards for safety and EMC. CE Marked; RoHS Compliant.

Statys PQT Software

- Three levels of test system login: Operator, Engineer or Administrator

- Operator selectable, pre-defined system configurations for a repeatable and controlled test environment

- Integrated test article pass/fail/undetermined selectable flags

- Concurrent real-time display and recording of hydrodynamic and video data

- Recording of multiple cycles of both hydrodynamic and high-speed video data

- Online measurement tools for acquired video images

- Integrated bar code scanner and digital stamping of video images

- Real-time safeguards to protect both the system and test samples

- 21 CFR Part 11 compliant with automatically generated test reports

Accessories

- Bar Code Scanner:

- For absolute traceability, the integrated bar code scanner will acquire the test article identification and document it within the software and test report.

- High Speed Camera(s):

- Up to 5 high speed cameras at 1280×1024 resolution are available for the system to provide high fidelity when documenting the leaflet kinematics.

- Automated Image Analysis:

- Automated image analysis algorithms interrogate the capture video to automatically determine key valve attributes automatically through software algorithms.

- Ultrasonic Flow Meter:

- Temporal, inline flow is measured and documented with a customized, ultrasonic flow meter located just proximal to the heart valve test article.

- Stainless Steel Assembly:

- To enable the entire test assembly to be autoclaved, the PQT-5000 can be manufactured completely from stainless steel and other autoclave compatible materials.

- Calibration Image Reference:

- Custom designed calibration reference of all camera to convert pixels to physical dimensions (e.g. millimeters).

- Adjustable Lighting Source:

- Optimal system adjustable LED lighting system that includes either ring or panel lights to optimal video imaging.

- Heating Circulation Valve:

- System valve to utilize at a test article to facilitate heating during initiation of test system.

- Auto-Refill Pump:

- Integration of a system controlled pump to replenish any fluid lost during valve exchange and maintain a consistent system fluid level during operation facilitates an additional gain in operator and system efficiency.