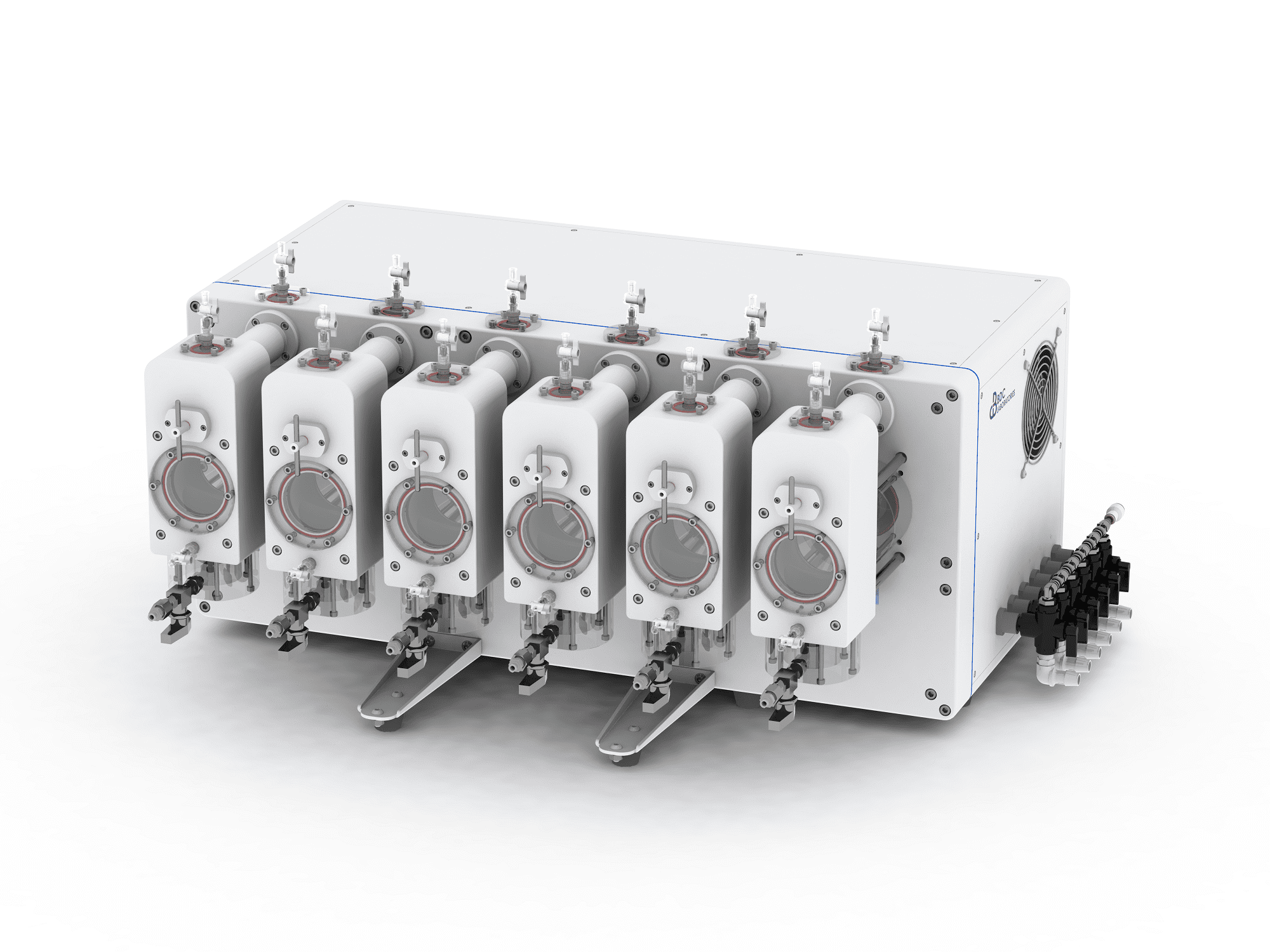

VDT-3600i Heart Valve Durability System

BDC Laboratories’ VDT-3600i heart valve durability tester is a patented, revolutionary accelerated wear test (AWT) system designed for evaluation modern transcatheter and surgical aortic, mitral, pulmonary and tricuspid valve technologies to meet ISO 5840 requirements. The test system has 6 completely independent test stations, incorporating 6 completely independent electromagnetic drivers, which allows each test station to be set totally independently in both displacement and frequency. The VDT-3600i heart valve accelerated wear tester moves the fluid through the test valve using our proven RB-5 driver technology to produce the opening and closing dynamics representative of clinical performance at accelerated frequencies up to 50 Hz. The VDT-3600i heart valve durability system is available in both a 6-station and 2-station platform.

The VDT-3600i valve durability system is controlled and monitored by our proprietary Statys® VDT closed-loop control and monitoring test software. There are many unique and patented features integrated into the software package as highlighted below, including: driver excitation waveform definition and control, differential pressure waveform analyzer with a ISO criteria specific counter, closed-loop control on differential pressure loading, continual monitoring of the real-time differential pressures in all test stations and individual station alarm capabilities for monitoring of test conditions.

Move Forward with BDC

Specifications & Benefits

- Six independent test stations / six independent drivers:

- Test different size heart valves simultaneously

- Test different heart valve configurations simultaneously

- Set each station to different test conditions

- Sample Capacity: 1 to 6 samples

- Sample Sizes: Up to 95 mm

- Excitation Waveforms: Sine & Modified Sine (std), Arbitrary (optional)

- Test Fluid: Water, Saline, PBS Solution

- Operating Frequency: 5 Hz (300 cpm) to 50 Hz (3000 cpm)*

- Heart Valve Differential Loading Capability: 500 mm Hg

- Operating Temperature: Room to 50 °C

- Regulatory Compliance: Complies with ISO 5840, and all applicable European Union directives and standards for safety and EMC. CE Marked; RoHS Compliant.

*actual test frequency is dependent upon heart valve size, frequency & target displacement

Statys VDT Software

- Patented arbitrary waveform driver excitation with integrated waveform creator to minimize pressure spike at accelerated frequencies

- Loading waveform analyzer for each station to determine test adherence to ISO 5840 with independent loading criteria cycle counter

- Closed-loop, autopilot driver control to user defined target differential pressure loading on each station

- Independent control of each test station’s excitation waveform, frequency and stroke conditions

- Simultaneous continual monitoring and logging of the real-time differential pressures of all test stations

- Real-time alarms and safeguards to protect both the system and test samples

- User-focused software environment to facilitate ease of system operation

Accessories

- ISO Criteria Waveform Analyzer:

- The ISO Criteria Waveform Analyzer is a software module that determines whether every waveform of each valve met the ISO differential pressure loading criteria. After data have been processed, the statistical results are displayed along with an overlay of the waveforms themselves. Included is a secondary cycle counter that enumerates the total number of loading cycles actually meeting the ISO differential pressure loading requirements.

- Arbitrary Waveform Creator:

- The Arbitrary Waveform Creator module enables the user to define and save customized motion waveforms. These waveforms can then be loaded and run by each station motor, allowing the user to optimize the opening and closing performance for the particular test valve.

- Alarm Output Trigger:

- The Alarm Output Trigger option allows the user to configure a digital signal for use in triggering external hardware in the case of a system alarm.

- Comprehensive Temperature Monitoring:

- To monitor and document each test stations fluid temperature simultaneously and independently, the comprehensive temperature monitoring system updates the system software and hardware to accommodate six temperature probes rather than the standard single probe the accompanies the system.

- Synchronized Snapshot Data Acquisition:

- When one desires the ability to synchronize the accelerated leaflet kinematics of the heart valve on test with the differential pressure loading, the synchronized snapshot data feature includes a TTL output signal that is time-matched to the waveform data acquisition for input to a high-speed camera system.

- Low Pressure Regulator:

- The Low Pressure Regulator is a precision pressure regulator designed for applications that require high resolution such as the VDT-3600i System. The Regulator features control sensitivity of 1/8″ water column, a pressure range of 0-10 psi, and a balanced supply valve to deliver consistent and reliable accuracy to maintain the system desired set point regardless of supply pressure changes or flow conditions.

- Silent Air Compressor:

- The optional Silent Air Compressor is a whisper quiet air compressor featuring an inline regulator and moisture trap with a noise level of a mere 30 dB. The Compressor features a convenient carry handle on top with an operating pressure range of 55-85 psi.

- Silicone Mock Vessels:

- BDC Labs offers certified silicone mock vessels in straight, curved, bifurcated or custom, customer defined configurations for mounting transcatheter heart valve frames and other endovascular implants on the VDT-3600i. Our mock vessels can be fabricated and certified to a diametric compliance or wall thickness, and the certification can be performed at various pulse pressures to meet your specific requirements (e.g., 160 mmHg/80 mmHg).