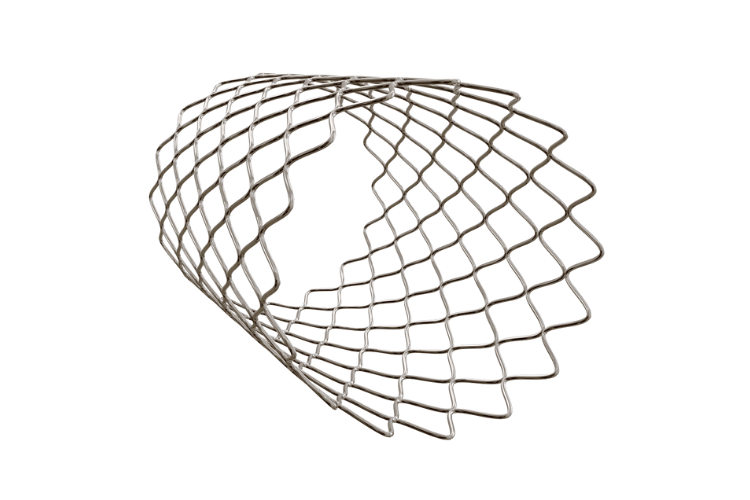

Stent & Stent Graft Testing

Experts from BDC Laboratories are actively involved in the AAMI/ISO 25539 Standard Workgroup (WG3), which covers Endovascular Prostheses (Part 1) and Vascular Stents (Part 2). We also participate in the ASTM Endovascular Prosthesis Standards Committee, which continuously works to establish testing methods for stent testing and stent graft testing.

Service Highlights

Standards-Driven Excellence

BDC Laboratories’ comprehensive internal stent and stent graft testing capabilities, per the respective published guidance documents, appear below.

Complete Testing Solution

Our team supports all aspects of medical device assessment, including developing the testing strategy, establishing protocols, performing data analyses, and providing regulatory quality final reports.

Scalable Test Program

We execute all test programs according to the data’s application, ranging from abbreviated early-stage development studies to final, formal regulatory submission studies.

Custom Evaluation Options

In addition to the noted tests, BDC Laboratories excels in developing custom test methods specific to novel and unique endovascular technologies.

Relevant Standards

ISO Standards

25539-1 & 25539-2

Implant

- Dimensional Verification

- Diameter to Balloon Inflation Pressure

- Length to Diameter Relationship

- Recoil

- Integral Water Permeability

- Water Entry Pressure

- Fabric Water Permeability

- Burst/Circumferential Strength

- Crush Resistance (Flat Plate & Radial)

- Flex/Kink

- Local Compression

- Longitudinal Tensile Strength

- Migration Resistance

- Modular Pull Strength

- Magnetic Resonance Imaging (MRI) Safety

- Radial Force

- Strength After Repeated Puncture

- Graft to Stent Attachment Strength

- Corrosion Assessment

- Radial Durability

- Bending Durability

- Axial Durability

- Torsional Durability

- Dislodgement Force

- Dogboning

- Profile Effect/Flaring

- Stent-Free Surface Area

Endovascular System

- Dimensional Verification

- Profile/Diameter

- Hemostasis

- Simulated Use

- Force to Deploy

Delivery System

-

- Balloon Inflation / Deflation Time

- Balloon Rated Burst Pressure

- Balloon Volume to Burst

- Balloon Rated Fatigue

- Tensile Bond Strength

- Torsional Bond Strength

- Tubing Longitudinal Tensile Strength

ASTM Standards

- F2052: Measurement of Magnetically Induced Displacement Force on Medical Devices in the Magnetic Resonance Environment

- F2079: Measuring Intrinsic Elastic Recoil of Balloon-Expandable Stents

- F2081: Characterization and Presentation of the Dimensional Attributes of Vascular Stents

- F2119: Evaluation of MR Image Artifacts from Passive Implants

- F2129: Standard Test Method for Conducting Cyclic Potentiodynamic Polarization Measurements to Determine the Corrosion Susceptibility of Small Implant Devices

- F2182: Measurement of Radio Frequency Induced Heating On or Near Passive Implants During Magnetic Resonance Imaging (MRI)

- F2213: Measurement of Magnetically Induced Torque on Medical Devices in the Magnetic Resonance Environment

- F2394: Measuring Securement of Balloon Expandable Vascular Stent Mounted on Delivery System

- F2477: In vitro Pulsatile Durability Testing of Vascular Stents

- F2503: Marking Medical Devices and Other Items for Safety in the Magnetic Resonance Environment

- F2743: Coating Inspection and Acute Particulate Characterization of Coated Drug-Eluting Vascular Stent Systems

- F2942: In vitro Axial, Bending, and Torsional Durability Testing of Vascular Stents

- F3044: Test Method for Standard Test Method for Evaluating the Potential for Galvanic Corrosion for Medical Implants

- F3067: Radial Loading of Balloon Expandable and Self Expanding Vascular Stents

FDA Guidance

Intravascular Stents and Delivery Systems

- Stent Corrosion Resistance

- Dimensional Verification

- Percent Surface Area

- Foreshortening

- Recoil

- Stent Integrity

- Radial Stiffness / Radial Strength

- Mechanical Properties

- Durability Testing

- Particulate Evaluation

- Magnetic Resonance Imaging (MRI) Safety and Compatibility

- Crush Resistance

- Kink Resistance

- Delivery, Deployment, Retraction

- Balloon Rated Burst Pressure

- Balloon Fatigue

- Stent Diameter vs. Balloon Pressure

- Catheter Bond Strength

- Crossing Profile

- Balloon Inflation / Deflation Time

- Stent Securement

Testing Backed by ISO/IEC 17025 Accreditation

At BDC Laboratories, quality is central to everything we do. We maintain ISO/IEC 17025:2017 accreditation and comply with relevant portions of 21 CFR Part 58 (Good Laboratory Practices), among other U.S. and international governing standards. With a comprehensive quality management system, we ensure service and product integrity with a focus on regulatory compliance and continuous improvement.

Why BDC?

Built Around Your Goals

From first conversation to final report, we collaborate with your team to design and execute accredited testing programs aligned with your device goals and regulatory requirements.

Regulatory-Ready, On Time

With ISO/IEC 17025:2017 accreditation and 40+ years of industry experience, we deliver precise, regulatory-ready results on timelines that keep your project moving.

Reliable, Responsive Partnership

You’ll work with project managers who stay engaged throughout the process. They’re available for questions, quick to respond, and focused on keeping your program on track.

Explore More

LDT-1800 | Uniaxial Fatigue System

RDT-7600i | Pulsatile Durability System

Connect with an Expert at BDC

Provide a few details about your project, and a BDC Laboratories team member will respond within 2 business days to advise on next steps.