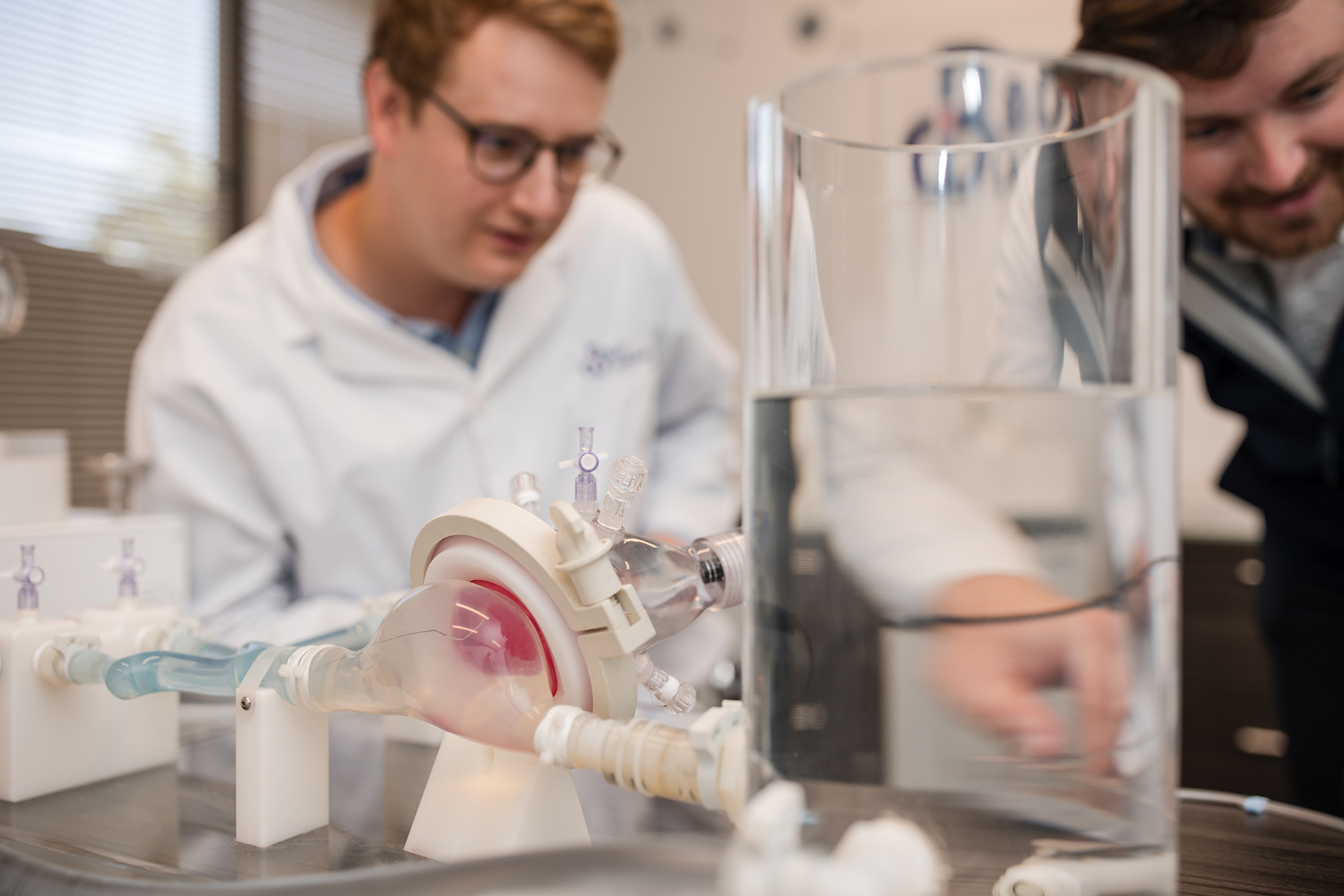

Silicone Mock Vessels

Precision-Crafted to Match Your Specifications

BDC Laboratories manufactures silicone mock vessels in nearly any configuration, with diameters ranging from 1.5 mm to over 50 mm. Options include straights, bifurcations, trifurcations, aortic arches with branch vessels, coronary “U” vessels, as well as silicone heart valves, atriums, and ventricles.

Each vessel is built to your specifications and can incorporate disease states as needed. Flanges or embedded rigid rings can also be added for secure mounting into a larger lest apparatus.

Quality Control

If your silicone vessels and anatomical models require an additional level of quality control, BDC Laboratories can measure the vessel’s key attribute(s) and provide Certification of Compliance with delivery. We use our fully validated dynamic compliance test system to determine dynamic radial compliance and pressurized inner diameters. If you order multiple vessels, the BDC team will test each one against the required specifications.

Dynamic Compliance

We can certify the dynamic radial compliance of our mock vessels to ISO 7198 and ASTM F2477 for durability studies or other applications requiring specific dynamic radial compliance. Compliance can be customized when wall thickness is not critical.

Controlled Wall Thickness

Wall thickness can be tailored to your specifications to achieve the desired structural performance or match physiological conditions. Wall thickness can be customized when compliance is not critical.

Vessel Configurations

BDC Laboratories produces silicone mock vessels in diverse geometries. Vessels can be verified and certified for geometry, wall thickness, and compliance to meet specific testing requirements.

Straight

Linear vessel segments for controlled evaluation of device performance across defined diameters and lengths.

U-Vessel

Curved geometries that replicate physiological bends to assess device functional performance and fatigue and durability in a challenging condition.

Bifurcated & Custom

Branching or complex anatomies, including patient-specific and disease-state models for advanced testing and training.

Anatomical Additions

Optional technologies are available to increase model fidelity and tailor systems to specific clinical use cases. These technologies support more realistic simulation and device interaction.

SLIC™ Friction Reduction Coating

BDC Laboratories’ proprietary SLIC™ Friction Reduction Coating is engineered to provide a clinically relevant surface friction profile for silicone anatomical models.

Echogenic Treatment

BDC Laboratories’ echogenic treatment alters the properties of silicone vessels to more accurately replicate how real anatomical structures appear under clinical ultrasound imaging.

Calcification

BDC Laboratories can integrate custom calcified lesions into any location with vascular or anatomical models, including coronary arteries and aortic valves.

Why BDC?

Custom-Designed for Your Application

From first conversation through final delivery, we work closely with your team to create silicone vessels engineered to match your specifications.

Expertise You Can Rely On

With 15+ years in silicone vessel fabrication and 40+ in cardiovascular device evaluation, we design for durability and regulatory alignment as needed.

Verified to Meet Your Specifications

Our vessels are manufactured with rigorous quality controls, ensuring that each model meets the dimensional and performance criteria your application demands.

Explore More

Testing Equipment Brochure

Testing Services Brochure

Silicone Vessels Brochure

Simulation Solutions Brochure

Connect with an Expert at BDC

Provide a few details about your project, and a BDC Laboratories team member will respond within 2 business days to advise on next steps.