About BDC Laboratories

Technical Experts in Medical Device Testing and Simulation

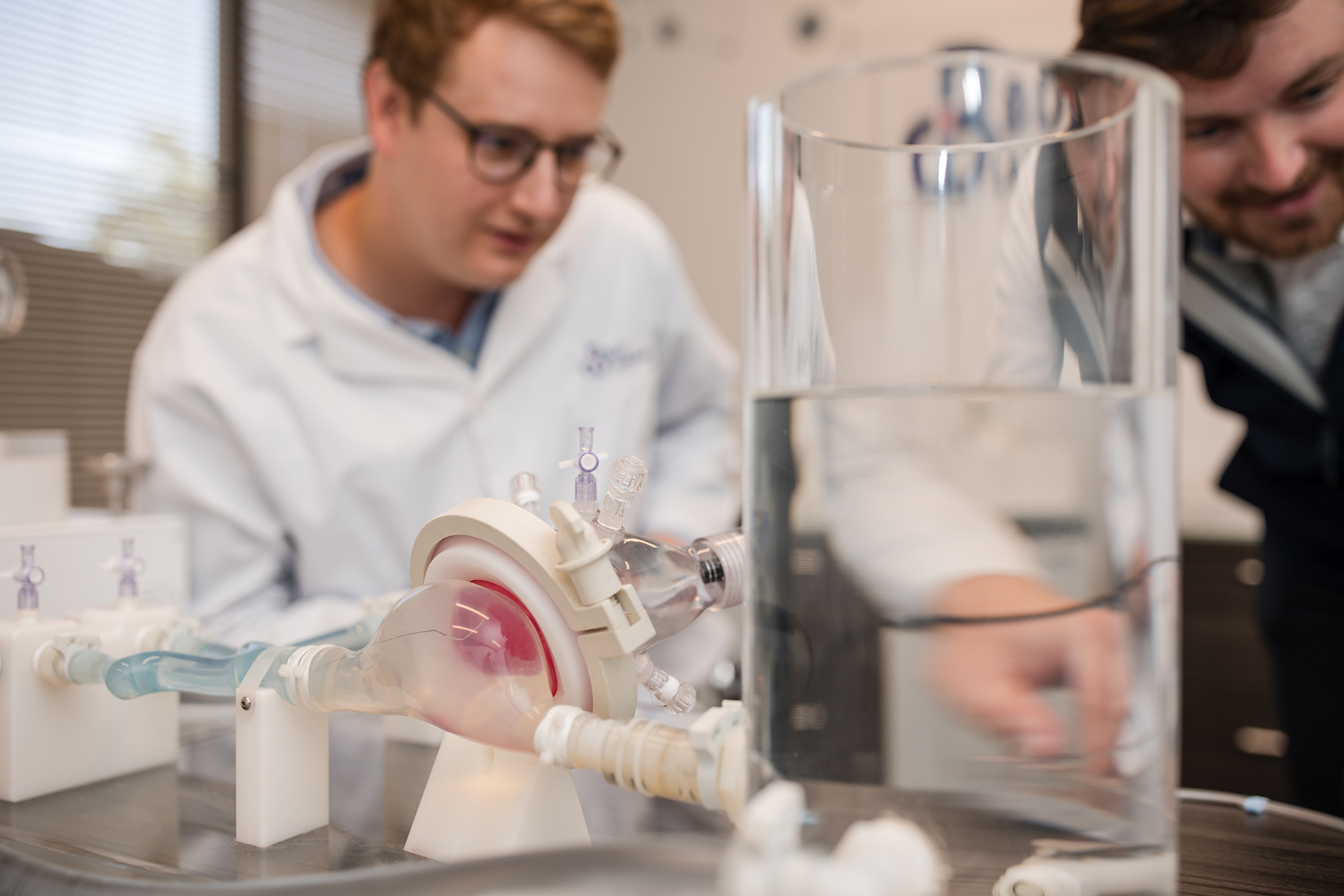

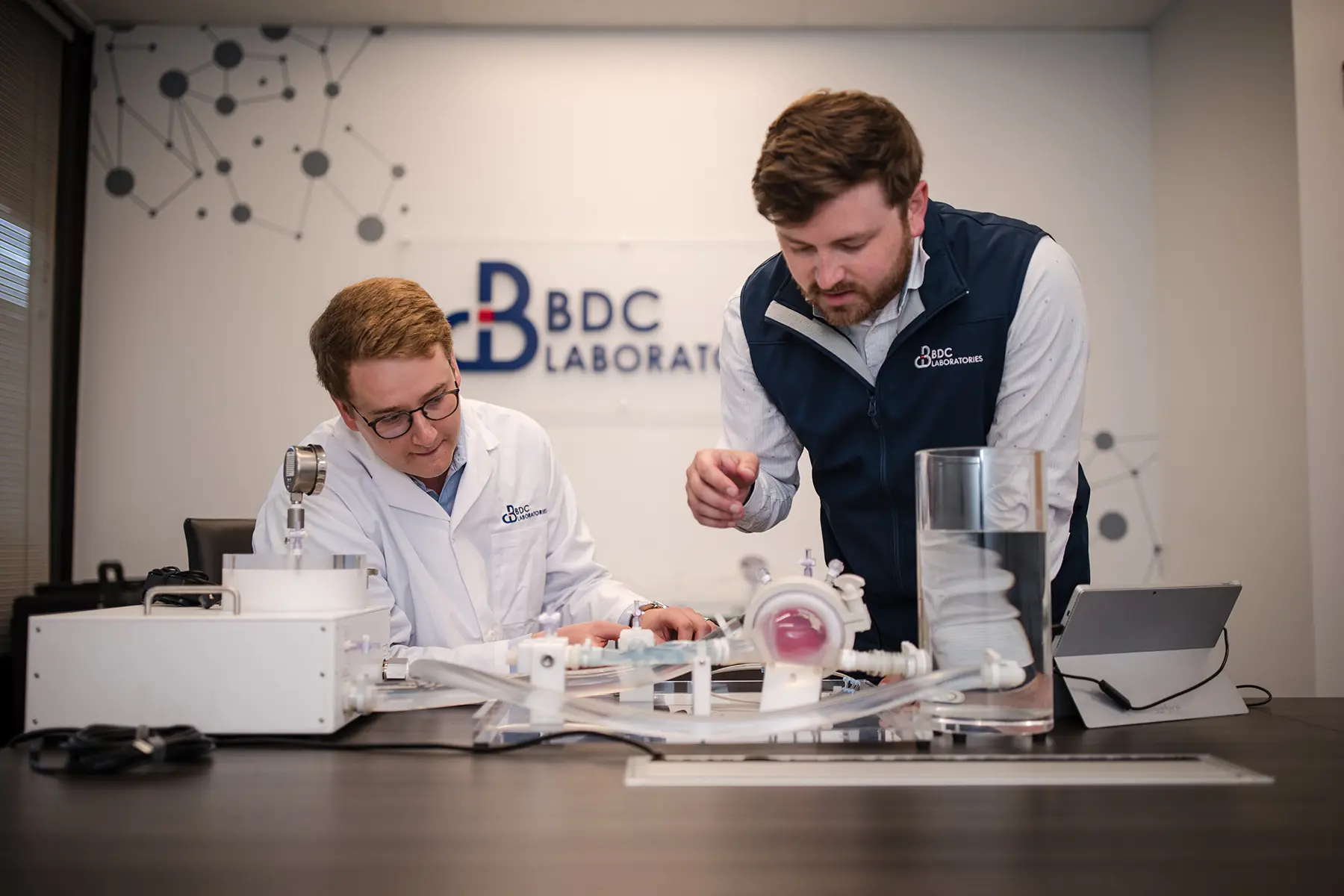

Medical device development is complex, and the testing process is equally intricate. That’s why BDC Laboratories partners with R&D teams to create a flexible path to reliable, timely testing for medical implants and their delivery systems. Supporting clients through the entire development cycle, we also design and develop precise silicone vessels for simulation and training when it’s time to go to market.

We’re a team of technical experts energized by the goal of helping our partners develop medical devices that improve healthcare outcomes worldwide. Known for our extensive experience in cardiovascular and endovascular device evaluation, we collaborate with engineering teams to test medical device designs through both testing services and fully delivered test systems.

As active participants in the AAMI, ISO, and ASTM International Endovascular Device and Stent Standards committees, we contribute our technical expertise to advance the quality and effectiveness of medical devices.

The mission of BDC Laboratories is to offer products and services to the medical device industry that aid in functional evaluation of technologies as related to clinical outcomes.

How We Work

Level-Set

We dedicate time to discussing the nuances of your medical device and its application, design, and technical requirements.

Brainstorm

Our technical experts ideate on the most effective and efficient way to test or simulate your device.

Sync

We present our plan to ensure we’re aligned before moving forward.

Design

The team gets to work, maintaining our rigorous quality standards and updating you along the way.

Delivery

We share our validated final test results, system, or simulation, and make sure you have what you need to keep moving forward.

Level-Set

We dedicate time to discussing the nuances of your medical device and its application, design, and technical requirements.

Brainstorm

Our technical experts ideate on the most effective and efficient way to test or simulate your device.

Sync

We present our plan to ensure we’re aligned before moving forward.

Design

The team gets to work, maintaining our rigorous quality standards and updating you along the way.

Delivery

We share our validated final test results, system, or simulation, and make sure you have what you need to keep moving forward.

Leadership

Bill Carlson

Craig Weinberg, Ph.D.

Brian Choules, Ph.D.

Dustin Homan

Renee Hiser

Erin Walters

Nate Elsen

Ben McCloskey

Lucas Calloway

Demonstrating Industry Leadership

Backed by 40 years of experience in medical device R&D, BDC Laboratories focuses on the functional, engineering-based testing of medical devices including Class 2 and Class 3 implants. The BDC team actively participates in the following standards committees:

American Association of Medical Instrumentation (AAMI)

International Standards Organization (ISO) Endovascular Device and Stent Standards Committee

ASTM Endovascular Device and Stent Standards Committee

As committee participants, BDC personnel have a unique understanding of medical device testing verification plans and protocols to support U.S. FDA and CE Mark submissions. BDC has a fully established quality system that’s based on Good Laboratory Practices (GLP) and accredited to ISO/IEC 17025:2017.

Our History

1977

Steven Weinberg, Ph.D. froms BDC Laboratories as a consulting company for medical device R&D support

1985

Establishes testing services and a Good Laboratory Practices (GLP) quality system

2006

Craig Weinberg, Ph.D. joins the company and tailors products and services to the evaluation of cardiac, endovascular, and vascular medical device technologies

2015

Initially accredited to ISO/IEC 17025

2017

Joins the Tentamus Group, a global network of highly specialized medical device and product testing labs

2022

Completes all electromagnetic compatibility (EMC) and safety testing of test systems for CE Mark approval